Determining the Right Time for York YVAA Microchannel Replacement in Industrial HVAC Systems

In the realm of industrial equipment, where precision and efficiency are paramount, the York YVAA microchannel plays a pivotal role in the performance of HVAC systems. Over time, factors such as wear, corrosion, and technological advancements may necessitate York YVAA microchannel replacement. This article aims to provide insights into recognizing the signs and circumstances indicating the need for replacement, emphasizing the importance of timely action to ensure optimal industrial cooling efficiency.

-

Understanding York YVAA Microchannels in Industrial HVAC Systems:

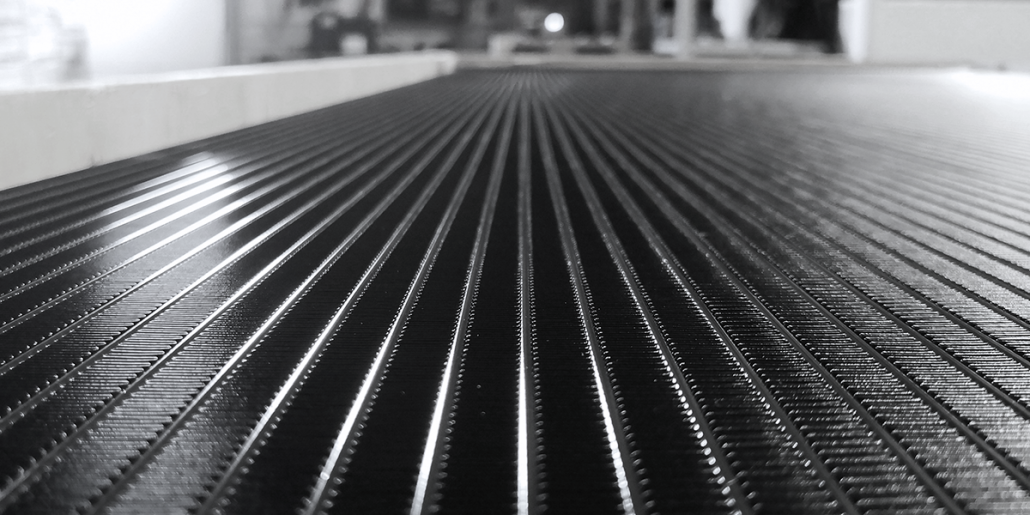

The York YVAA microchannel is a critical component in the refrigeration cycle of HVAC systems, specifically in air-cooled chillers within industrial settings. These microchannels facilitate efficient heat dissipation, ensuring the transformation of refrigerant from a gas to a liquid state. Recognizing the need for York YVAA microchannel replacement involves understanding the key factors that can impact the performance and lifespan of these components.

-

Signs Indicating the Need for York YVAA Microchannel Replacement:

Diminished Cooling Capacity:

One of the primary signs that it’s time for York YVAA microchannel replacement is a noticeable reduction in cooling capacity. If the HVAC system struggles to maintain the desired temperature or exhibits uneven cooling, it may be an indication that the microchannels are no longer operating at optimal efficiency.

Increased Energy Consumption:

As microchannels wear out or become inefficient, the HVAC system may require more energy to achieve the same level of cooling. A spike in energy consumption without a corresponding increase in cooling efficiency suggests that the microchannels may be reaching the end of their functional lifespan.

Corrosion and Physical Damage:

Visual inspections are crucial in identifying the need for York YVAA microchannel replacement. Corrosion, rust, or physical damage to the microchannels can compromise their integrity, leading to reduced efficiency and the potential for refrigerant leaks.

Frequent Repairs:

If the HVAC system requires frequent repairs, especially related to microchannel issues, it may be more cost-effective in the long run to opt for York YVAA microchannel replacement. Persistent problems indicate that the microchannels are no longer operating optimally.

-

Technological Advancements:

In the ever-evolving landscape of HVAC technology, newer and more efficient microchannels are continually being developed. If the existing microchannels are outdated and incompatible with the latest advancements, it might be prudent to consider York YVAA microchannel replacement to leverage the benefits of cutting-edge technology.

The Importance of Timely York YVAA Microchannel Replacement:

Preventing System Downtime:

HVAC systems are critical to the uninterrupted operation of industrial facilities. Timely York YVAA microchannel replacement helps prevent unexpected breakdowns, reducing system downtime and ensuring that the cooling infrastructure remains reliable.

Optimizing Energy Efficiency:

A worn-out or inefficient microchannel can lead to increased energy consumption. Timely replacement ensures that the HVAC system operates at peak efficiency, contributing to energy savings and aligning with sustainability goals.

Preserving System Integrity:

Addressing the need for York YVAA microchannel replacement in a timely manner is crucial for preserving the overall integrity of the HVAC system. This proactive approach helps prevent issues such as refrigerant leaks, which could compromise the efficiency and effectiveness of the entire cooling system.

Maximizing Longevity:

York YVAA microchannel replacement is an investment in the longevity of the HVAC system. By replacing worn-out components with new, durable microchannels, industrial facilities can extend the lifespan of their cooling infrastructure, reducing the frequency of repairs and replacements.

The York YVAA Microchannel Replacement Process:

System Assessment:

The process begins with a comprehensive assessment of the existing HVAC system. Trained technicians evaluate the condition of the current microchannels, considering factors such as wear, corrosion, and overall performance. This assessment forms the basis for determining the need for York YVAA microchannel replacement.

Customized Solutions:

York offers a range of YVAA microchannel options to suit various industrial HVAC applications. The replacement process involves selecting the most suitable York YVAA microchannel based on the specific requirements of the facility. Customization options ensure seamless integration into existing systems.

Professional Installation:

York YVAA microchannel replacement is a precision task that requires professional installation. Technicians adeptly remove the existing microchannels and install the new York YVAA microchannels with precision, ensuring optimal performance and longevity.

Performance Testing:

Post-installation, the HVAC system undergoes rigorous performance testing. This includes evaluating heat dissipation efficiency, refrigerant levels, and overall system functionality. York YVAA microchannel replacement aims not just to replace worn components but to elevate the performance of the entire HVAC system.

Conclusion: Proactive York YVAA Microchannel Replacement for Optimal Industrial Cooling Efficiency

In conclusion, recognizing the signs indicating the need for York YVAA microchannel replacement is essential for maintaining optimal industrial cooling efficiency. Timely action, backed by comprehensive assessments and professional installation, ensures that the HVAC system operates at peak performance. Proactively addressing the need for York YVAA microchannel replacement not only prevents system downtime but also contributes to energy efficiency, system longevity, and the overall reliability of industrial cooling infrastructure. In the dynamic landscape of industrial equipment, staying attuned to the condition of microchannels and embracing timely replacement is key to sustaining efficient and uninterrupted operations.