Benefits Of A Geometric Laser Measurement System

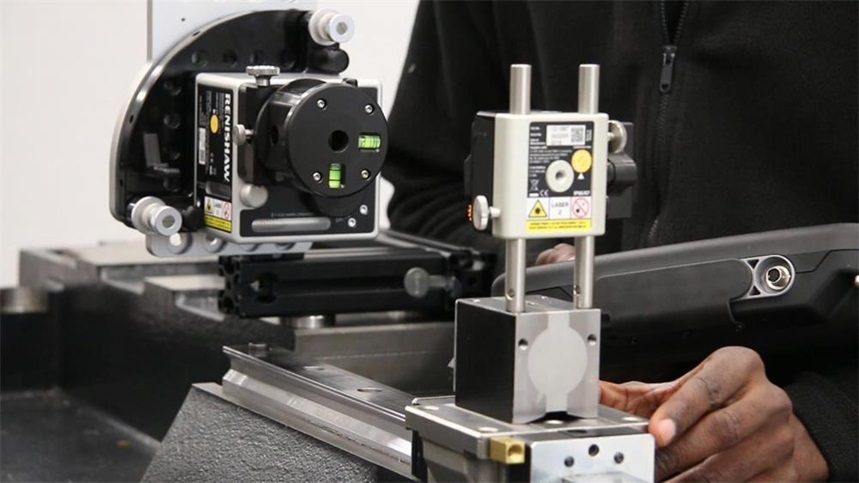

Using Laser geometric measurement tools is advantageous for any business using precision tools or equipment. When you can utilize the best possible systems to analyze and correct your alignment, you can ensure you are implementing the best possible production processes. With more accurate operation and reduced downtime, this can be advantageous for industries. Getting your machine geometry right is the foundation of effective and efficient operation and optimized production.

If your alignment is off, it could create a crooked movement or uneven surface, which will, in turn, skew the final results – getting progressively worse over time. Using a laser system to check your machines is more straightforward and accurate than older, more traditional technologies. With the effective processes in place, you can produce more precise alignment and check every plane for even optimum surface levels. Read on to find out more about these devices and their solutions.

Why Use This System?

Correct machine solutions are needed to ensure your operations meet quality standards. Maintenance and analysis allow you to keep every machine running within defined parameters and tolerances, helping cut down on waste. Older systems such as stones or dial gauges were groundbreaking in their day. Still, today we have a better, far more effective solution in laser options better suited to modern machinery.

Easy To Use

Laser systems offer businesses a lightweight and straightforward way to deal with misalignment. This method allows for quick and easy setup and simple preparations to get the job done. This means you can get better results and data points in far less time overall. In addition, reducing downtime for maintenance and more effective results in machine performance.

Distance Alignment

Laser systems can align and measure over long distances with accurate results. This gives you far more accessibility when considering the type of machine and area or can analyze accurately. All devices can be checked and aligned no matter their depth or location. Digital systems are not only quicker but offer a variety of other benefits, from quickly computing results to displaying comparative differences right away. This ensures that you understand the alignment needs right away, instead of having to analyze them separately.

Multi-Axis

There are both vertical and horizontal elements within a machine, giving you an X and Y axis to deal with. While many traditional methods are limited to which axis they can operate on, these new-age options ensure that one process can manage both planes. This accurately and effectively gives you truer readings for all elements involved.

Enhanced Accuracy

You can rely on the laser beam to always provide 100% straight and accurate references, giving you more accuracy no matter your setting. As alignment depends on accurate readings, this allows you to optimize operation far more than any traditional method.

Position Shifting

These devices also allow you to read and follow the alignment while making adjustments from any position. This allows for more maneuverability during readings, ensuring you can get the most accurate results from your maintenance and alignments tasks.

Date-Focused

Easily document your results electronically and transfer them to your computing network with a technological system. This makes it far easier to check and compare results immediately rather than taking time to analyze them closely. In addition, with a computer system at work, you can implement changes and guidelines in no time at all.

Whatever your operation, a geometric measurement system allows you complete control over your machine operations and business production. This is essential in ensuring your machines can function effectively at their optimum capacity, saving you and your business time and money. In addition, this laser method keeps your machine geometry in check and helps you deliver precision product quality at all times. The trusted, professional solution to machine alignment for several industries. Contact us today to find out more about these expert solutions.